RIDEX® Miter Rails

for Movable Bridges

Keeping You on Track

Our patented RIDEX® rail products have set the standard in the rail industry. They are installed in hundreds of bridges nationwide, including:

Vertical Lift Bridges

Single Leaf Bascules

Double Leaf Bascules

Swing Bridges

Why RIDEX® Miter Rails?

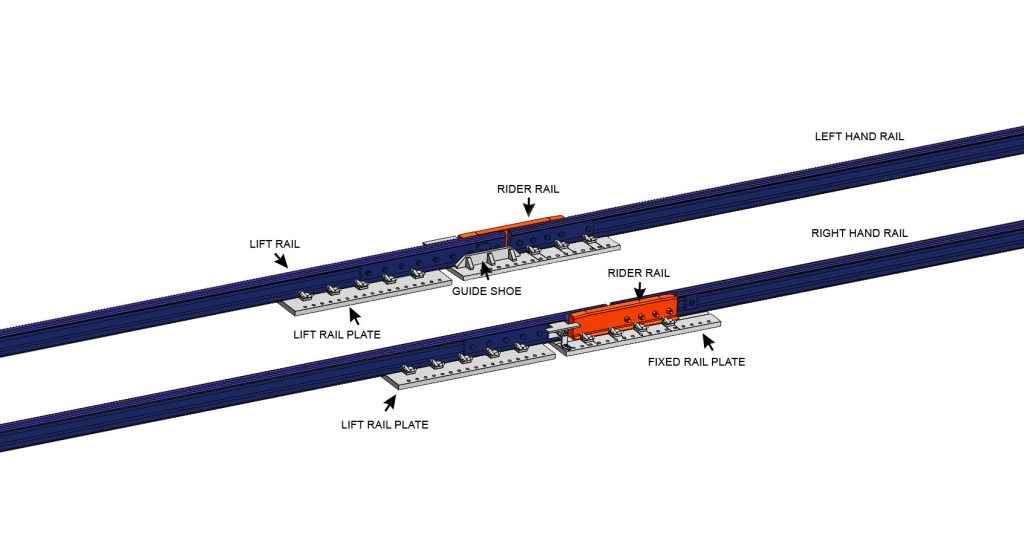

The RIDEX® Miter Rail System

(also known as the Rider Rail System) brings you:

1

Patented Design

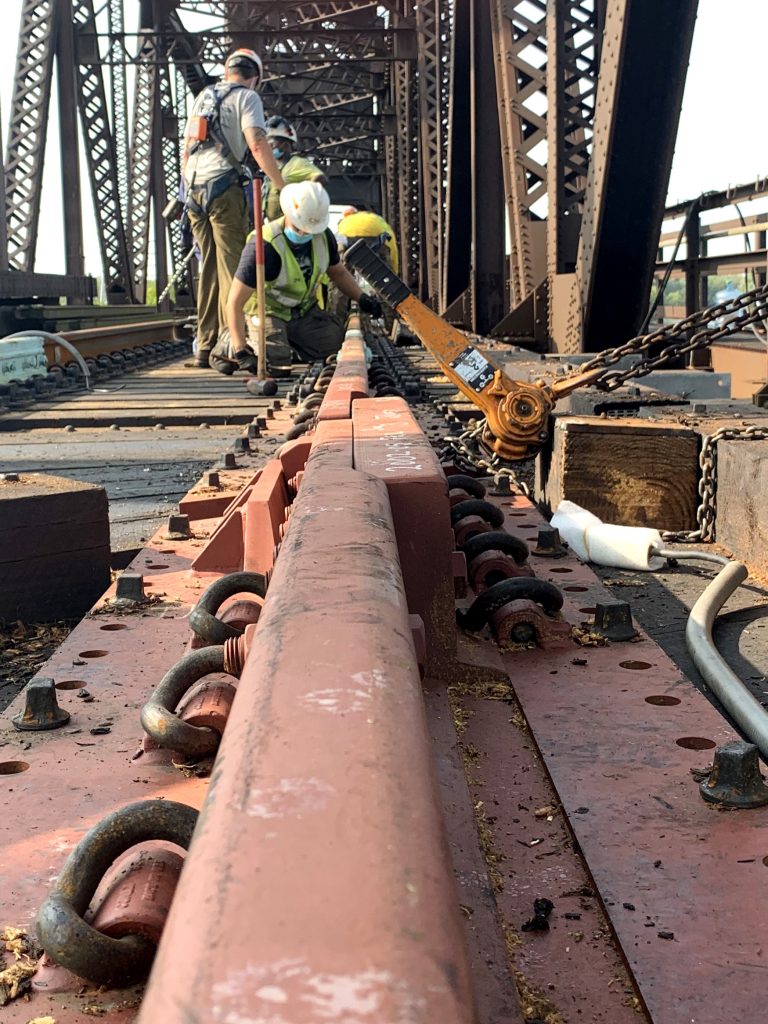

We machine both fixed rails and lift rails from lengths of new rail and add the “rider rail” to provide a seamless transition between the two. The rider rail is bolted to the fixed rail and remains stationary. It is slightly lower than the running rail at its ends and slightly higher than the running rail at its center — this gentle radius smoothly carries the train wheel over the gap between rails.

2

Expansion Capabilities

The gap between the lift and fixed rails is generally set at several inches, depending on bridge configuration and temperature. The expansion capabilities are significant, allowing several inches of movement.

3

Simple Maintenance

RIDEX® miter rails for movable bridges are manufactured from head-hardened rail and heat-hardened steel, making them stronger and more durable than the typical cast manganese systems, therefore requiring little maintenance. With the patented RIDEX® system, riders and rails that become worn over time can be replaced quickly by a two-person crew. This reduces the person-hours needed to make the replacement and minimizes track-outage time.

Your Custom RIDEX® System

To install a new bridge system or replace an existing one quickly and efficiently, simply contact us. We will survey your site and custom-machine a RIDEX® system uniquely fitted to your bridge, with an average lead time of just 4-6 weeks.

Contact Us

For more information about any of our products,

call us at (800) 381-5808 or reach out via email.